Case Studies...

Our customers are always facing challenges with packaging, as well as the need for innovation from manufacturing and retailers. At MAP we strive to find the best solutions for their challenges, simultaneously benefitting the customer and helping us innovate new packaging designs for the future! Our packaging design case studies show that we put our customer and their needs first, and we work hard to save them money wherever we can. Look through our library and see how we have helped our customer solve some of their toughest design problems!

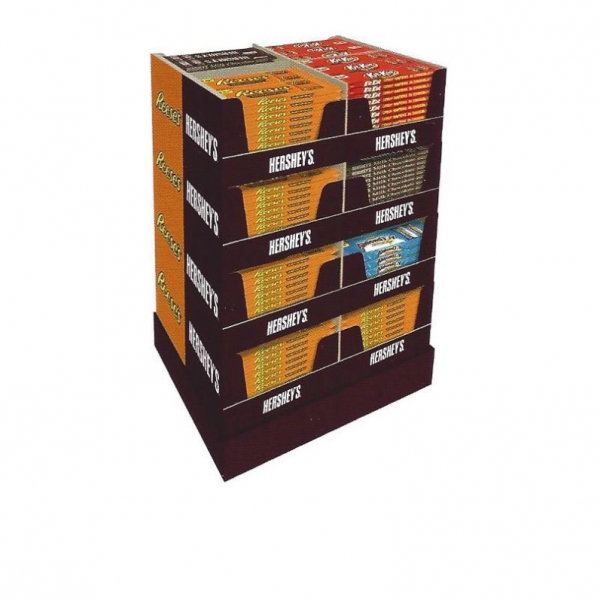

Hershey 8 Pack Quarter Mod

Hershey 8 Pack Quarter Mod

© 2001 - 2024 Mid-Atlantic Packaging, Inc. 436 Stump Rd. Montgomeryville, PA 18936 Phone: 215-362-5100

Designed By:{Lolio GD}